Management of the production floor

In the age of global competition, factories strive for efficiency and improved manufacturing processes. Managing the manufacturing floor is key in everything related to Industry 4.0. Now more than ever, factories understand the need for implementing a system that will manage and monitor the activity of the manufacturing floor and detect weaknesses. Trunovate of Contel Group is the leading company in Israel for consultation, characterization, and implementation of advanced manufacturing solutions. Our activity is focused on the identification of bottlenecks and weaknesses in the manufacturing chain, starting from the preparation of raw materials and ending in the packaging and delivery of the final product. We know how to adjust our solutions to the organization’s DNA and minimize the changes required for implementation. We are equipped with the experience, knowledge, and technology needed for completing an efficient project that will brand your factory as a leading force in its field.

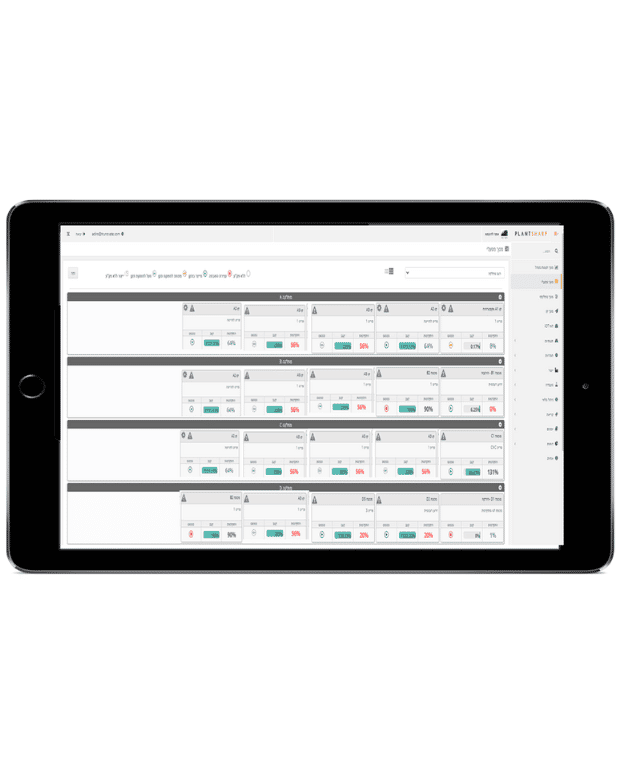

MES System

PlantSharp caters to the growing need for one robust system that connects to the factory’s components, analyzes the manufacturing indicators, and displays the data in real time. It helps the manager analyze all cumulative indicators, make informed decisions, and utilize the factory. Our MES solution is characterized by a modern, intuitive user experience that allows the workers to focus on manufacturing and operation.

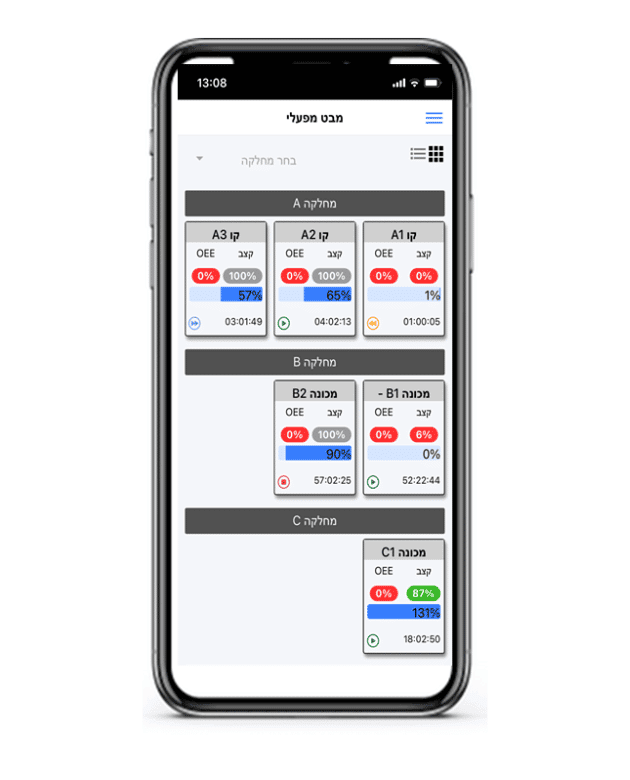

OEE System

This module manages and monitors the OEE indicators from the manufacturing machines. The solution is based on an infrastructural connection between the system and the factory’s control mechanism. It reads the OEE indicators and displays them in real time. The OEE indicator is crucial for ensuring the factory’s efficiency and enabling immediate response.

Traceability management

Management of all traceability parameters, definition of recipes, load-bearing pallets, manufacturing frames, and a designated operation screen with all of the required parameters.

Weighing management

A designated system for the management and control of the entire weighing mechanism in the factory- creation of premix processes, weight definition, scale location, scale communication, communication parameters, weight limits, identification and weighing of items for small packages, identification and weighing of materials for work commands, and identification of batches. The weighing process is carried out against real time control limits and the weight unit defined in the system.

Assignment planning module

A module that enables assignment of work commands to the manufacturing lines according to the defined manufacturing possibilities and tools. Work commands can be assigned by dragging the commands to the allotted time slots displayed for the different production halls. The module enables multiple displays according to timeline, day, week, and month.

Instructions module

Management of built-in processes in the manufacturing line, with the possibility to combine images, sketches, etc. The users follow a set of instructions relevant for their stations, and mark completed assignments. The system documents signatures of workers and/or shift managers for every task.

Laboratory module

Linkage of laboratory tests to the manufacturing process. This module tests all raw materials and products during all manufacturing stages and ensures that the products meet the quality standards determined by the factory.

Energy monitoring module

A module that serves for tracking the use of various types of energy such as electricity, gas, fuel, and water, while linking energy quantities and costs to the actual manufacturing data of the manufacturing lines. This module connects to the different energy gauges on the manufacturing lines and the peripheral equipment. It also provides possibilities for calculating direct and relative consumption from the manufacturing tools.