End of line solutions

MMTS, a subsidiary of Contel Technologies, is engaged in a wide variety of automation End of line solutions for industrial factories. The process starts with need characterization and ends with the installation and implementation of the solution. The service is provided by MMTS’s skilled technical team, which includes engineers and support personnel in the fields of mechanics, electricity, control and communication.

MMTS has 30 years’ experience in the implementation of independent systems and execution of projects in the turn key method. As a subsidiary of Contel Technologies, MMTS offers a wide variety of solutions for manufacturing lines, including: packaging systems, transport systems, flattening systems, marking of products and surfaces, control and management systems, and provision of perishable packaging materials.

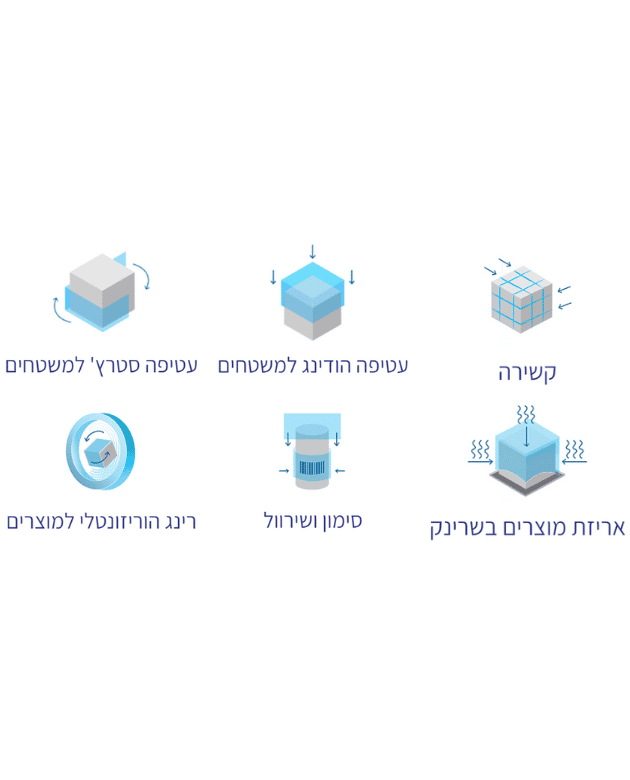

Among the advanced solutions of MMTS:

Packaging solutions

Tailored solutions for packaging products of various types. The objective is to improve the manufacturing process in the plants while accelerating the packaging process and making it more stable and accurate. All of the above per the client’s requests.

Marking of products and surfaces

The marking is carried out in a variety of methods including ink injection, laser, marking directly on the cartons or printing and applying tags. The user can mark on a wide variety of materials including plastic, rubber and metals.

The marking application is chosen according to the type of material, operation requirements, manufacturing pace and line end environment.

Provision of perishable packaging materials

The holistic End of line solutions of MMTS include also the provision of packaging materials and their adjustment to the machine, such as attachment ribbons, pp, pet, metal attachment ribbons, devices for the attachment ribbons, machine stretch, manual stretch, scotch tape, closures for attachment ribbons, and more.

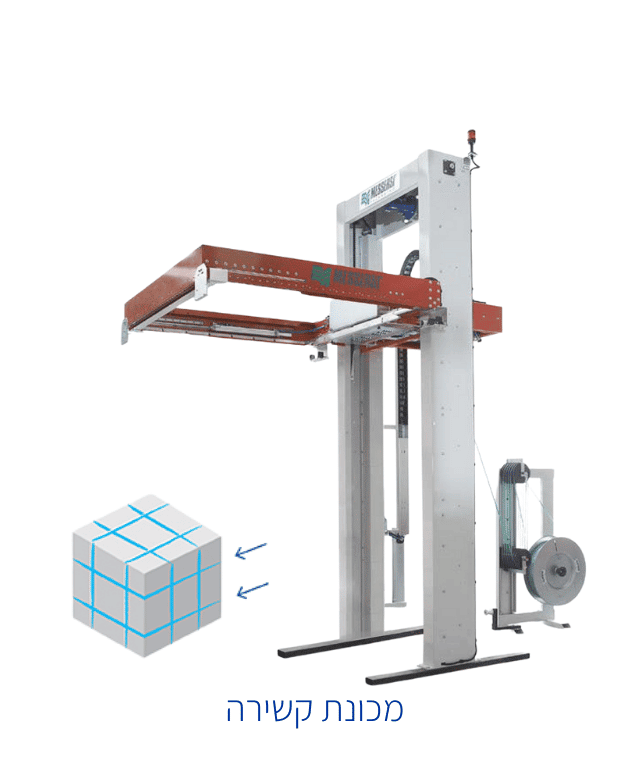

Attachment systems

Automatic or semi-automatic systems for attaching surfaces and products.

Vertical or horizontal attachment machines for a wide variety of industries that cater to the needs of the manufacturing lines.

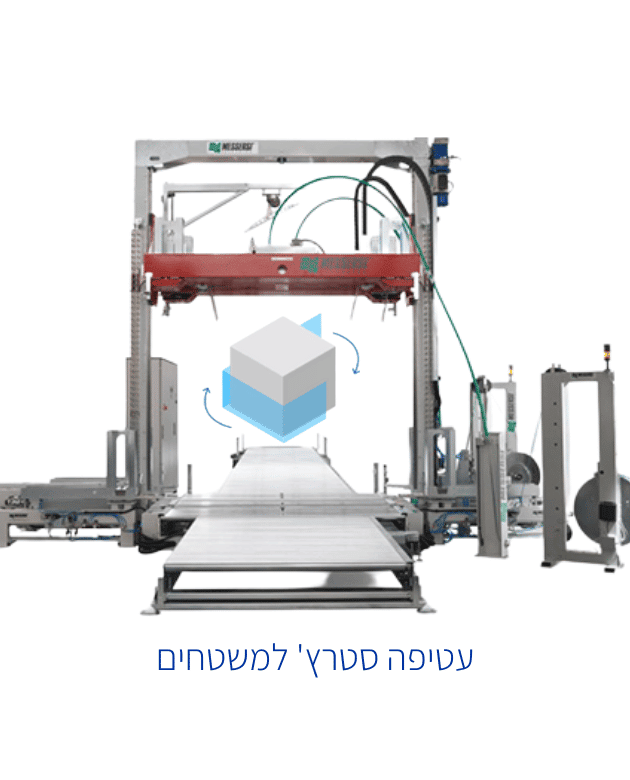

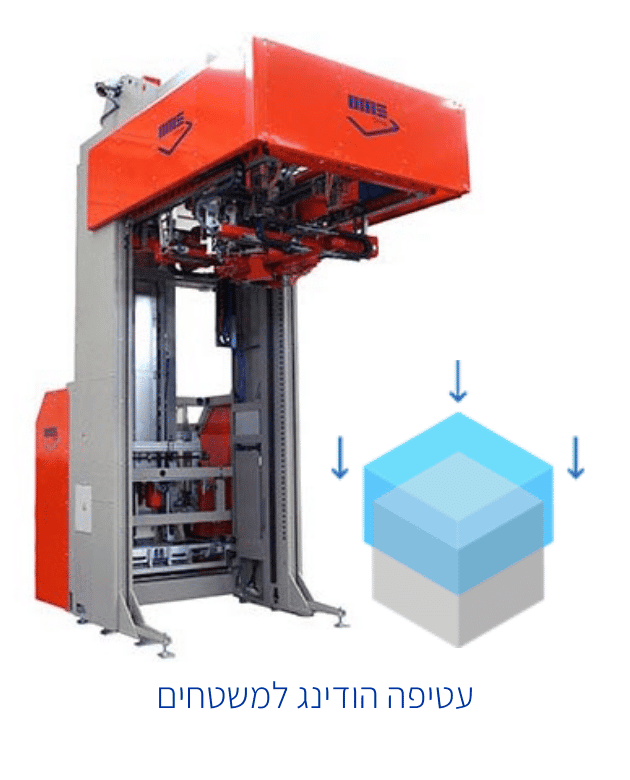

Surface wrapping systems in the stretch or hooding methods

Automatic and semi-automatic systems for wrapping surfaces.

This allows the client to wrap products in the free stretch or hooding stretch methods.

The wrapper protects the product from water and dust.

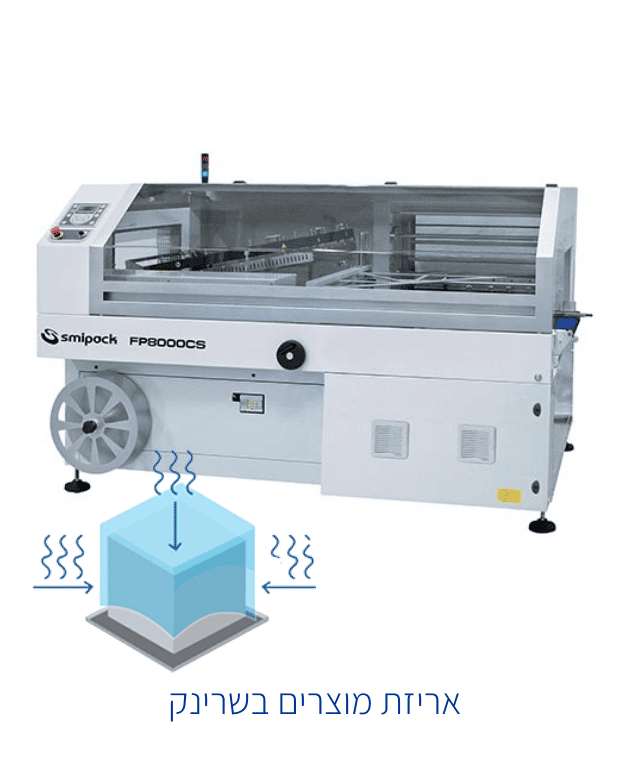

Shrink systems

Automatic or semi-automatic systems for packaging products in the shrink method. The machines enable maximum adjustment to the size of the packages, and allow you to determine the number of packages to be welded with an electronic meter. There are systems that enable work with a printed sheet, as well as pad cartons at the bottom of the system.

Pick and place systems

A system suitable for a variety of industries whose objective is to gather products automatically with a gripper inside cartons, and open and close cartons automatically. The system lifts the products and places them on the surface in an accurate, fast manner. The systems are suitable for products of various sizes and weights.

Sleeving Systems

Automatic systems for sleeving single products. The machines sleeve products in the shrink method, at a pace of more than ten products per second, at a high level of accuracy. This enables a more efficient, convenient control of the machine.

Carton assembly and closure systems

Systems that automatically close and assemble cartons in manufacturing lines or packaging. Suitable for cartons in a variety of sizes with upper or bottom closure.

Transport and flattening systems

Characterization and manufacturing of transport systems and conveyor belts in manufacturing lines and flattening systems for the arrangement of packages and products. the flatteners are made by Scaligera.